As an essential fat-soluble vitamin for the human body, vitamin D has core functions including promoting calcium and phosphorus absorption, maintaining bone health, and playing an important role in immune regulation, metabolic balance, cardiovascular function, etc. Adequate vitamin D intake not only helps prevent osteoporosis and rickets, but also supports the immune system to fight infections and chronic diseases.

There are two main forms of vitamin D commonly found on the market: vitamin D3 (cholecalciferol, mainly derived from animal raw materials or lanolin) and vitamin D2 (ergocalciferol, mostly extracted from fungi or plants). In recent years, the differences between the two in bioavailability, stability and applicable populations have become the focus of industry attention.

This article aims to help brand owners and formulators gain a deeper understanding of the characteristics of vitamin D3 and D2, help them choose vitamin D raw materials that are more suitable for product needs, optimize product formulations, and improve consumers’ health benefits.

Comparative Analysis of Vitamin D3 and D2

Chemical Properties And Physiological Effects

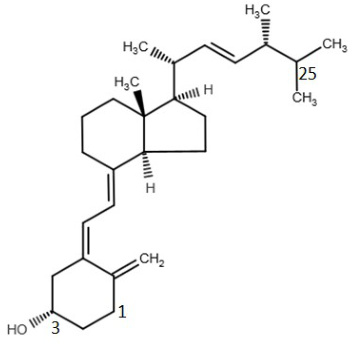

Vitamin D3:

- Structure: steroid structure, single bond side chain, containing methyl group.

- Metabolic pathway: requires two-step activation in the liver (25-hydroxylation) and kidney (1α-hydroxylation) to convert into the active form 1,25-dihydroxycholecalciferol, which has a biological activity 50% higher than the precursor.

- Function: directly promotes calcium and phosphorus absorption, enhances bone density; regulates immune T cell activity, and reduces inflammatory response.

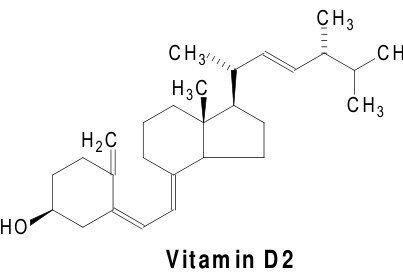

Vitamin D2:

- Structure: The steroid core is similar to D3, but the side chain contains double bonds and additional methyl groups, which affect metabolic efficiency.

- Metabolic pathway: It needs to be converted into 1,25-dihydroxyergocalciferol, but its half-life is short (19-48 days) and its storage capacity is weak.

- Function: Similar to D3, but with lower potency, especially when supplemented at high doses.

Comparing Half-life And Bioavailability

Half-life:

Vitamin D3 and its 25-hydroxy metabolite have a longer half-life in the blood (about 15 days to 3 weeks), while vitamin D2 has a shorter half-life (about 10-15 days), which means that D3 stays in the body longer and maintains the vitamin D level in the blood for a longer time.

Bioavailability:

- Efficiency of serum 25(OH)D enhancement: Multiple meta-analyses have shown that D3 is about 87% higher than D2 in increasing serum 25(OH)D levels, and the effect is maintained for a longer time. For example, the effect of supplementing 1000 IU D3 daily is equivalent to 1.7 times that of D2.

- Mechanism difference: D3 has a higher affinity with vitamin D binding protein (DBP), slows renal clearance, and prolongs circulation time.

Stability And Storage Conditions

Vitamin D3:

- Strong stability, high temperature and humidity resistance, can be stored for a long time at 2-8°C in the dark.

- Suitable for a variety of dosage forms (such as oils, powders), especially excellent in high-temperature processed foods.

Vitamin D2:

- Sensitive to light and oxygen, easy to degrade, and needs to be stored strictly in a dry place away from light (0-8°C).

- The degradation rate is high in liquid preparations, and it is recommended to be used in low-temperature processed products.

Scientific Research and Clinical Trial Data

Vitamind3 Raises 25(Oh)D More Effectively Than D2

Multiple clinical studies have confirmed that vitamin D3 is more advantageous in improving and maintaining serum 25(OH)D levels:

| Aspect | Vitamin D3 | Vitamin D2 | Notes |

| Dose Efficiency | Raises serum 25(OH)D levels 20-30% more than D2 at the same dose | Lower increase in serum 25(OH)D compared to D3 | Meta-analysis (Tripkovic et al., 2012, AJCN) |

| Single 50,000 IU dose: serum peak 57% higher than D2 | Significantly lower peak serum levels | Armas et al., 2004, RCT | |

| Half-life and Persistence | Half-life ~15 days, maintains stable blood levels | Half-life 3-5 days, requires more frequent dosing | Armas et al., 2004; Biancuzzo et al., 2010 |

| Special Populations | Higher bioavailability in obese, elderly, and malabsorption patients | Relatively lower bioavailability | Holick MF, 2007; Wagner CL et al., 2013 |

Advantages Of Using Vitamin D2

Although D3 has better performance, D2 is still irreplaceable in specific scenarios:

- Pure plant/fungal source: D2 is extracted from yeast or mushrooms irradiated by ultraviolet light, which meets the needs of strict vegetarians (Vegan) and religious diets (such as kosher and halal food), and is the core raw material of plant-based products.

- No animal allergy risk: For people with animal protein allergies or special dietary taboos, D2 is safer as a non-animal source supplement.

Clinical Feedback From Patients With Vitamin D Deficiency

Studies on patients with vitamin D deficiency have shown that there are significant differences in the clinical effects of D3 and D2:

Common deficiency patients:

- D3 is more efficient in correcting severe deficiency (serum 25(OH)D <20 ng/mL). For example, a study on adults showed that patients who supplemented with 50,000 IU D3 per week had an average 25(OH)D level of 40 ng/mL after 8 weeks, while the D2 group only reached 28 ng/mL (Armas et al., 2004).

- D3 has a more significant improvement on bone health indicators (such as bone density and parathyroid hormone levels), especially in postmenopausal women (Bischoff-Ferrari et al., 2012).

Vegetarians or patients on special diets:

Studies on vegetarians have shown that D2 needs to be supplemented at a higher dose (about 1.5-2 times that of D3) to achieve the same serum 25(OH)D level, but it may still not completely replace the biological activity of D3 due to metabolic differences.

Patients with hepatic and renal insufficiency:

The metabolites of D2 (such as 24-hydroxylated derivatives) may accumulate due to decreased renal clearance, while the metabolic pathway of D3 is closer to endogenous vitamin D and has better safety.

Practical Application in Supplement Formulation

Common Dosage Forms And Processing Precautions Of Vitamin D3

Due to its high bioavailability and stability, vitamin D3 is widely used in a variety of dosage forms. It needs to be selected in combination with formulation requirements and production process optimization:

Common dosage forms:

- Soft capsules: medium-chain triglycerides (MCT oil) or olive oil as carriers, suitable for high-dose (such as 2000-5000 IU/capsule) supplementation, light-proof packaging can reduce oxidation.

- Oil-based drops: the first choice for infants or people with dysphagia, antioxidants (such as mixed tocopherols) need to be added and water activity controlled to prevent hydrolysis.

- Tablets/powders: D3 is encapsulated by microencapsulation or spray drying technology, suitable for solid beverages or chewable tablets, but high-temperature tableting processes need to be avoided (may cause 10-15% loss of activity).

- Dairy/plant milk: D3 is soluble in milk fat or plant oils (such as sunflower oil in oat milk), and attention should be paid to the homogenization process to ensure uniform dispersion.

Processing precautions:

- Avoid light and oxygen: Inert gas (such as nitrogen) should be used for filling during the production process, and the packaging material should be brown glass or aluminum-plastic light-proof material.

- Temperature control: Avoid long-term high-temperature treatment (such as hot-filled beverages need to be quickly cooled to below 40°C).

- Incompatible: Avoid direct contact with strong oxidants (such as hydrogen peroxide) or highly acidic ingredients (pH <3).

Use Scenarios And Limitations Of Vitamin D2

Although vitamin D3 occupies the mainstream market, vitamin D2 still has unique value in specific fields, but its limitations should be noted:

Use scenarios:

- Suitable for pure plant-based or vegetarian supplements to meet the needs of strict vegetarians and vegans.

- Commonly found in mushroom extracts and plant-based multi-dimensional products.

- Widely used as a substitute for vitamin D in some countries and markets.

Formula limitations and coping strategies

- Low bioavailability: The efficacy of D2 in increasing serum 25(OH)D is only 50-70% of that of D3, and dose compensation (increasing the dose by 20-30%) or combined with calcium and magnesium are required to enhance the bone effect.

- Poor stability: The degradation rate of D2 in liquid preparations is 2-3 times higher than that of D3. It is recommended to use it preferentially in low-temperature processed products (such as cold-pressed juice) or add light stabilizers (such as titanium dioxide).

- Risk of metabolic interference: D2 metabolites (such as 24-hydroxyergocalciferol) may inhibit the activity of endogenous D3, and long-term high-dose use (>4000 IU/day) should be avoided.

Market Demand: Plant-Based vs Non-Plant-Based

Cost comparison and influencing factors:

| Dimension | Vitamin D3 | Vitamin D2 |

| Raw Material Cost | Low (Lanolin extraction process is mature) | Higher (Depends on UV conversion efficiency) |

| Production Process | Scalable synthesis (purity ≥99%) | Requires precise UV light exposure (wavelength error ≤5 nm) |

| Supply Chain Stability | High (Mainly produced in China, Europe) | Medium (Dependent on mushroom/yeast supply) |

| Cost Note | D3 raw materials cost ~30% less than D2; lanolin is stable and abundant (global yield >100,000 tons/year) | Mushroom-based D2 requires UV treatment (approx. $500/ton) and incurs plant-based certification costs (e.g., Vegan Society) |

Market price fluctuations: The price of D3 is greatly affected by lanolin production (climate, animal welfare regulations), while the cost of D2 is driven down by fungal culture technology (such as yeast strain improvement).

Regulatory and Certification Considerations

Acceptance And Regulatory Requirements Of D3 And D2 In Different Markets

There are significant differences in the regulation of vitamin D3 and D2 in major global markets, which directly affects raw material selection and product positioning:

| Region/Market | Vitamin D3 | Vitamin D2 |

| European Union | – Approved for food fortification (e.g., dairy, cereals) and dietary supplements. – EFSA recognizes D3’s superior bioavailability but requires animal-source disclosure (e.g., lanolin-derived must be labeled). | – Approved as a food additive (E 598) and supplement ingredient. – Plant origin supports “natural” and “vegan” labeling claims. |

| United States (FDA) | – GRAS status, widely used in foods and supplements. – “Vitamin D3” labeling permitted without animal source disclosure (unless allergen-related). | – GRAS status, must be labeled as “Vitamin D2” or “Ergocalciferol.” – Plant-based origin favored for USDA organic certification. |

| China | – Permitted as a nutritional fortifier (GB 14880) in dairy, infant foods, etc. – D3 must meet Chinese Pharmacopeia purity standard (≥97%). | – Approved but with narrower use (e.g., certain health foods). – Requires documentation of plant origin (e.g., fungal fermentation process). |

| India | – Permitted, though D2 remains dominant in prescriptions due to lower cost. – FSSAI requires source labeling (e.g., fish liver oil or lanolin). | – Commonly used as a first-line treatment for vitamin D deficiency (due to traditional practices and cost). |

| Middle East (Halal) | – Animal-based D3 must be Halal-certified (e.g., lanolin from compliant slaughter). | – Naturally Halal-compliant due to plant/fungal origin. |

| – Some conservative markets may restrict non-Halal sources. | – Generally does not require additional certification. |

Purity, Safety Standards And Certification System

Vitamin D raw materials must meet internationally accepted quality and safety standards. The key certifications and requirements are as follows:

| Certification / Standard | Vitamin D3 | Vitamin D2 |

| USP (United States Pharmacopeia) | – Purity ≥ 97%, potency ≥ 24,000 IU/g. – Requires testing for key impurities (e.g., previtamin D3, lanolin residues). | – Purity ≥ 97%, potency ≥ 40,000 IU/g. – Must control ergosterol residues and oxidation byproducts. |

| EP (European Pharmacopoeia) | – 25-hydroxyvitamin D3 content must be < 0.1%. – Heavy metal limits (e.g., lead < 1 ppm). | – Strict control of ergocalciferol isomers (e.g., over-hydrogenated forms). |

| ISO 9001 / GMP | – Must comply with GMP (e.g., prevent cross-contamination). – Animal-derived sources must include BSE/TSE-free declaration. | – Fermentation process must verify microbial safety (e.g., no mycotoxin contamination). |

| Non-GMO Certification | – If derived from genetically modified yeast or microbes, must be labeled. – Lanolin-based D3 is typically considered non-GMO. | – Fungal fermentation D2 easily qualifies for Non-GMO Project verification (using traditional strains). |

Differences In Labeling Requirements

There are the following core differences in the labeling of vitamin D in global markets:

Vitamin D3

- Ingredient name: “Vitamin D3 (Cholecalciferol)” or “Cholecalciferol” must be marked.

- Allergen statement: If the source is cod liver oil or lanolin, it must be marked as “Contains fish/sheep derived ingredients”.

- Vegetarian label: Most D3s do not meet vegan standards and must be clearly marked

- Functional description compliance requirements: Subject to regulatory restrictions, such as “support bone health” must be supported by scientific evidence.

Vitamin D2

- Ingredient name: “Vitamin D2 (Ergocalciferol)” or “Ergocalciferol”.

- Allergen statement: Usually indicate “from mushrooms” or “plant-based”

- Vegetarian label: Can be declared as Vegan/Vegetarian

- Functional description compliance requirements: Efficacy claims are similar to D3, but it is necessary to indicate “suitable for vegetarians”. Some markets restrict the efficacy claims of D2.

Why choose SED Ingredients LTD Ingredients?

SED Ingredients is committed to providing customers with high-quality vitamin D3 and D2 raw materials that meet international standards. Our D3 raw materials are of high purity and excellent stability, and can be processed in a variety of dosage forms. Secondly, our vitamin D2 is made from high-quality plant raw materials and has been strictly tested for vegan formulations.

Our vitamin ingredients are quality controlled throughout the process and provide detailed test reports to help customers enter the global market smoothly.

Summary

Manufacturers and formulators should choose the most suitable vitamin D raw materials based on target consumer preferences, regulatory requirements and formulation characteristics. Welcome to contact SED Ingredients LTD to obtain detailed information and quotes on vitamin D ingredients!